Bridging the Gap Between Design and Operation with Better Models

In the evolving landscape of building energy systems, the shift towards model-based engineering is not a trend but a necessity. This approach promises a more integrated framework for designing and operating energy systems. Yet, challenges and opportunities lie ahead in this transition. While writing this article, I came across this work “A call to action for building energy system modelling in the age of decarbonization“, which gave me food for thoughts like few others. So, if you want a longer read on the need to change the way we think about models, there you go.

The Siloed Approach in System Design and Control

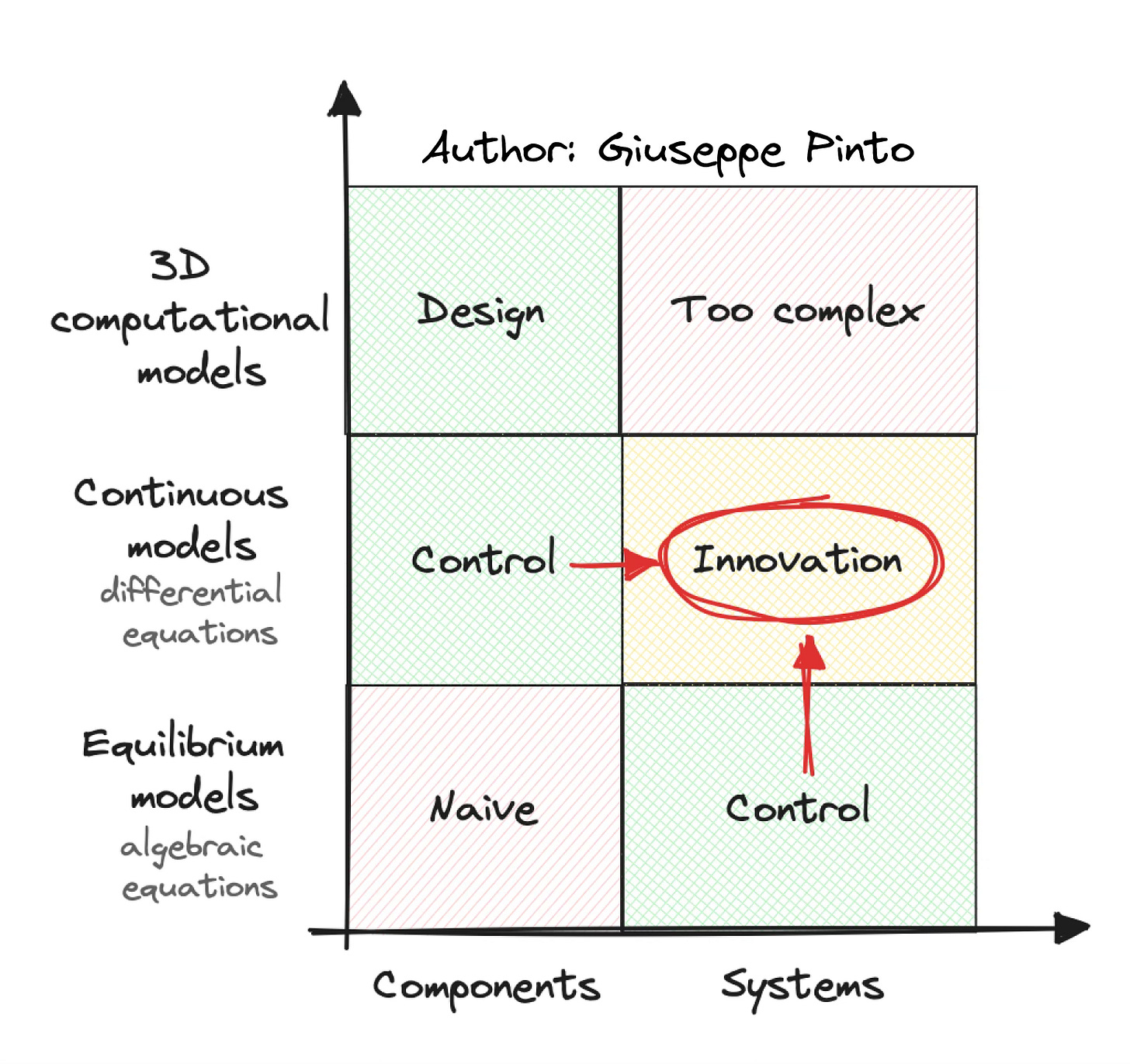

In the realm of building energy systems, we currently face a dichotomy. On one side, there's a traditional approach relying heavily on design-day calculations or load duration curves. This method often overlooks the dynamic nature of energy systems in buildings. The advantages lies in its modular approach, rather than a holistic one, that simplifies the process. However, given the rapid introduction of new technologies, this led to subsystems designed independently from one another.

A natural evolution is represented by parametric/generative design, that studies the system as a whole. This approach considers a broader range of variables and scenarios, offering a more holistic view of energy management.

There's a growing recognition of the need for a model-based engineering approach that couples design and control. However, right now these two approaches exist in silos, leaving off the table the opportunity of co-optimise the two.

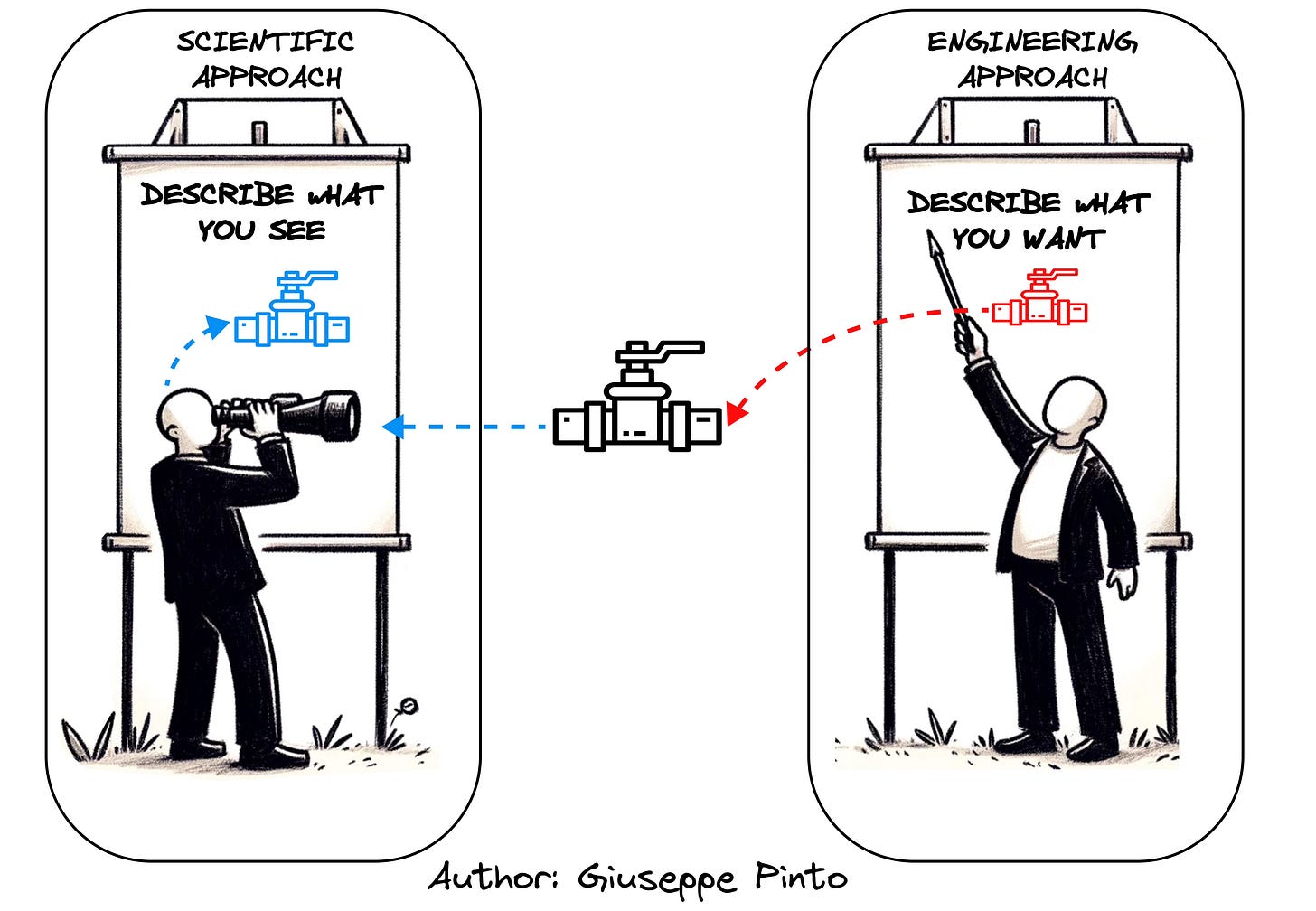

As a result, the industry is often using two models for the same thing. These models follows completely different paradigm, an engineering one and a scientific one. This concept is explained by Lee and Sirjani in the article: “What Good Are Models?”.

We can either choose (or invent) a model that is faithful to the [system], or we can choose (or invent) a [system] that is faithful to the model. The former is the essence of what a scientist does. The latter is the essence of what an engineer does.

In engineering, a model is useful if we can find an implementation that is reasonably faithful to the model. In science, a model is useful if it is reasonably faithful to a system given to us by nature. In other words, a scientist asks, ‘Can I make a model for this thing?’ and an engineer asks, ‘Can I make a thing for this model?

Untapping the potential of advanced control using differentiable detailed system models

The uncertainty in the design phase, combined with the inertia of established practices such as the use of PID controllers, have contributed to the use of simplified models and (not really) “advanced” control strategies. A way to unlock the benefits of truly advanced control strategies is to have better engineering models. So far, the main challenges are the following ones:

Load based simulation, feedback based control: Traditional simulators and advanced control strategies use load-based calculations for HVAC operations, differing significantly from real-world controls that respond to actual measurements like temperature or airflow. This leads to a gap between simulated and actual system performance, but also offering the possibility shift from a reactive to a predictive control approach.

Not so “white-box” models: Current simulators are based on (hidden) physical equations. This lead to either use continuous model that cannot be changed or equilibrium models that only focus on static phenomena, limiting the applicable control strategies. Additionally, current simulators often oversimplifies phenomena in favour of speed, especially those controlled by pressure and temperature dynamics.

Need for Differentiable Models: Another pain-point is related to simulator differentiability. The ability to differentiate these models is essential for calculating gradients, used to optimise control actions for future time steps like in Model Predictive Control (MPC).

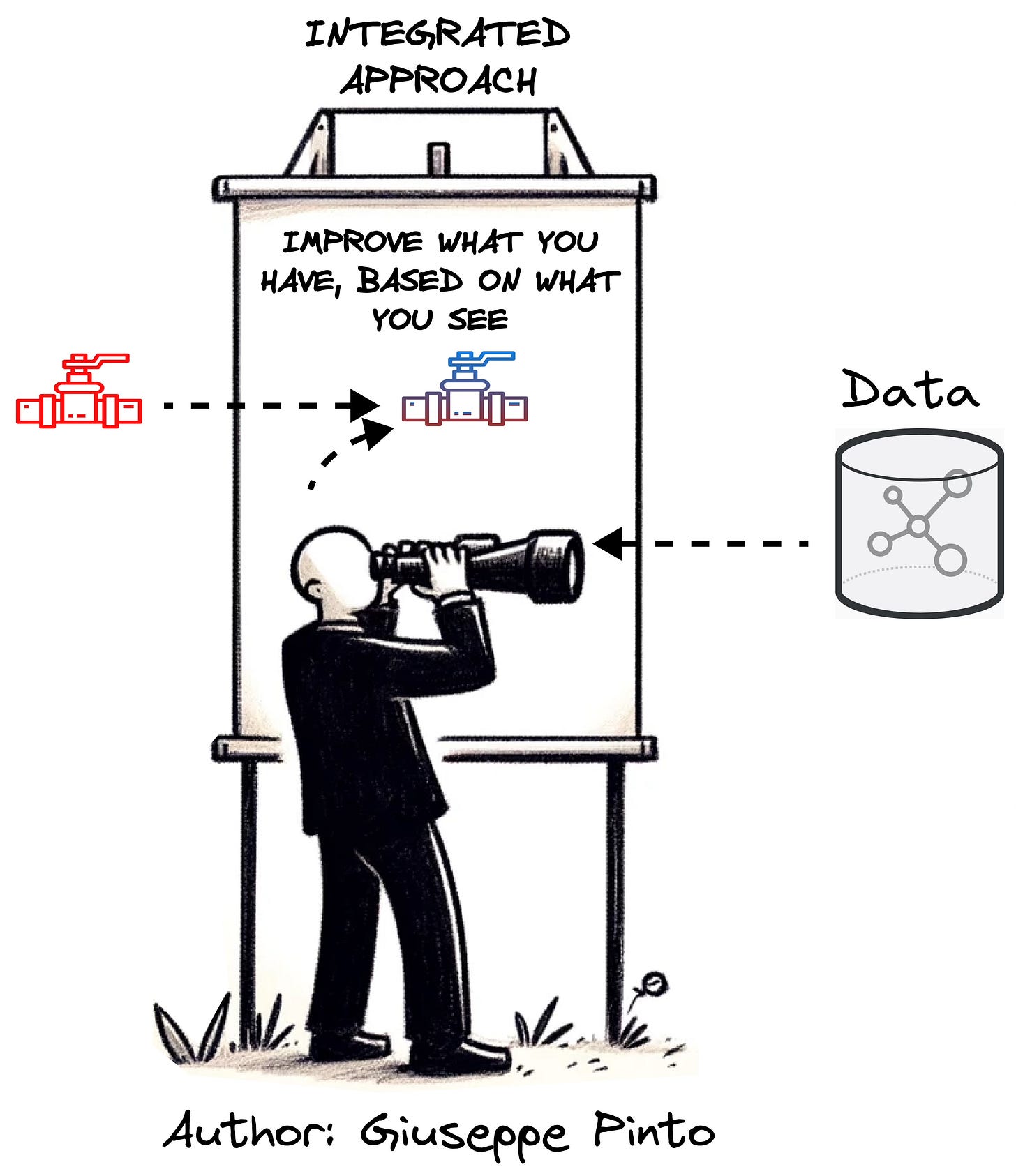

Furthermore, differentiable models can be integrated with machine learning algorithms unlocking a new way of combining physics and data (Scientific machine-learning).

These features allows the design of intelligent and autonomous building management systems, that can leverage detailed simulations to learn and optimise performance over time.

One ontology to rule them all

A key obstacle in scaling building energy models is the disconnect between design and operation. In terms of standards, two different approach have been developed to describe what’s in the building (ASHRAE 223P) and how to control the building (ASHRAE 231P). Luckily, these two standards have been designed to be complementary, integrating the design and operational phases of building energy systems.

Their integration, combined with detailed differentiable models would enable a continuous flow of information, allowing for real-time adjustments and optimisations based on actual performance data. This approach merges two models into one, creating a more realistic model that can interact with the building.

In conclusion, the future of building energy systems hinges on our ability to develop models that leverage physical laws while taking advantage from data. These models must possess distinct properties suitable for optimization, simulation, and control. By bridging the gaps between traditional and modern methods, and between design and operation, we can scale building energy models to support the deployment of autonomous buildings.