From Niche to Norm: Accelerating the adoption of advanced controllers in buildings

Recently, I have been thinking about the role of advanced controllers in energy management. There are many use cases that employ advanced process control (APC) for industrial facilities; however, finding their counterpart in the building domain is truly challenging. As a result, I tried to roughly quantify the number of buildings using advanced control and found this quote:

0.00001% of buildings have employed advanced controls, despite enormous amount of research - Donghun Kim (Berkeley Lab)1

This provocative number is based on the amount of published papers citing a real-world implementation. Of course, everything depends on the definition of advanced control, and I believe there are advanced controllers implemented but not associated with a paper. But, even considering a broad definition, I bet the number is not too far from reality.

In addition, what we consider advanced control strategies, such as Model Predictive Control (MPC) and Deep Reinforcement Learning (DRL), have been around for approximately 50 years each, compared to a 100-year-old PID. So yes, they are advanced, 50 years more advanced than what is found in 99.99% of buildings, but they were not invented yesterday. They have been waiting for the past 50 years, bottlenecked by computational costs and cost barriers.

Computational cost barriers

It is important to make a distinction between the effectiveness of control strategies and their application (or the lack thereof). DRL and MPC are not the same as they were 50 years ago. They continuously improved over time, sometimes at a faster pace than before, sometimes leveraging breakthroughs in other fields.

There have been two major improvements over the past 35 years:

The increase in computational power available from CPUs and GPUs

The improvement in algorithm/solver performances

To provide an idea of how much hardware and software have improved over the past 35 years, I always like to mention Moore’s Law for hardware and a talk by Robert Bixby (that you can find here) for solver/software improvements.

Most are familiar with Moore’s Law, which states that “the number of transistors in an integrated circuit doubles every year”. However, a less known fact (which I hope becomes a 'today I learned' moment for you) is that software improvements, particularly for solving mixed integer programming problems, have been just as significant, if not more so.

Since logarithms can be challenging to grasp, let’s put this in perspective: considering that the MIP solver has seen a 5 million improvement, and hardware a 4000 speedup2, (provocatively) assuming that the improvement of hardware and software could stack, a problem that would take 38000 years in the 90s, would take 60 seconds today (a 20 billion improvement).

Cost barriers

So, if we've seen huge improvements in problem-solving speed, why is the adoption of advanced controllers for energy management still, to put it mildly, a niche?

Unsurprisingly, the answer lies in the fact that the benefits of an advanced controller must outweigh the investment costs, the increase in complexity, and the engineering effort required.

It’s not that there are no applications; rather, they are limited to very specific use cases. When I started my PhD, I was amazed by the use of machine learning and DRL in big tech, thinking it would only be a matter of a couple of years before this approach became mainstream in many buildings (how naive).

Google: 30% improvement in data center

Microsoft: autonomous HVAC agent design

Amazon: HVAC control environment

The final goal was still heating and cooling, but the focus shifted more towards large buildings and data centers.

The main reason is that not every control system needs to be replaced with an advanced controller. Autonomous systems become autonomous only after deployment, but to “work like magic” on the field, they require a substantial amount of engineering effort, making them costly. As a result, not every project is suitable for an autonomous systems.

The general rule is:

The percentage improvement in key performance indicators should justify the project costs

Let's break it down with some examples. In the context of energy management, the primary goal of an advanced controller is to achieve (at best) a 30% energy saving. This means that, considering a payback period of two years, the cost of the project should be equal to 60% of the annual energy consumption

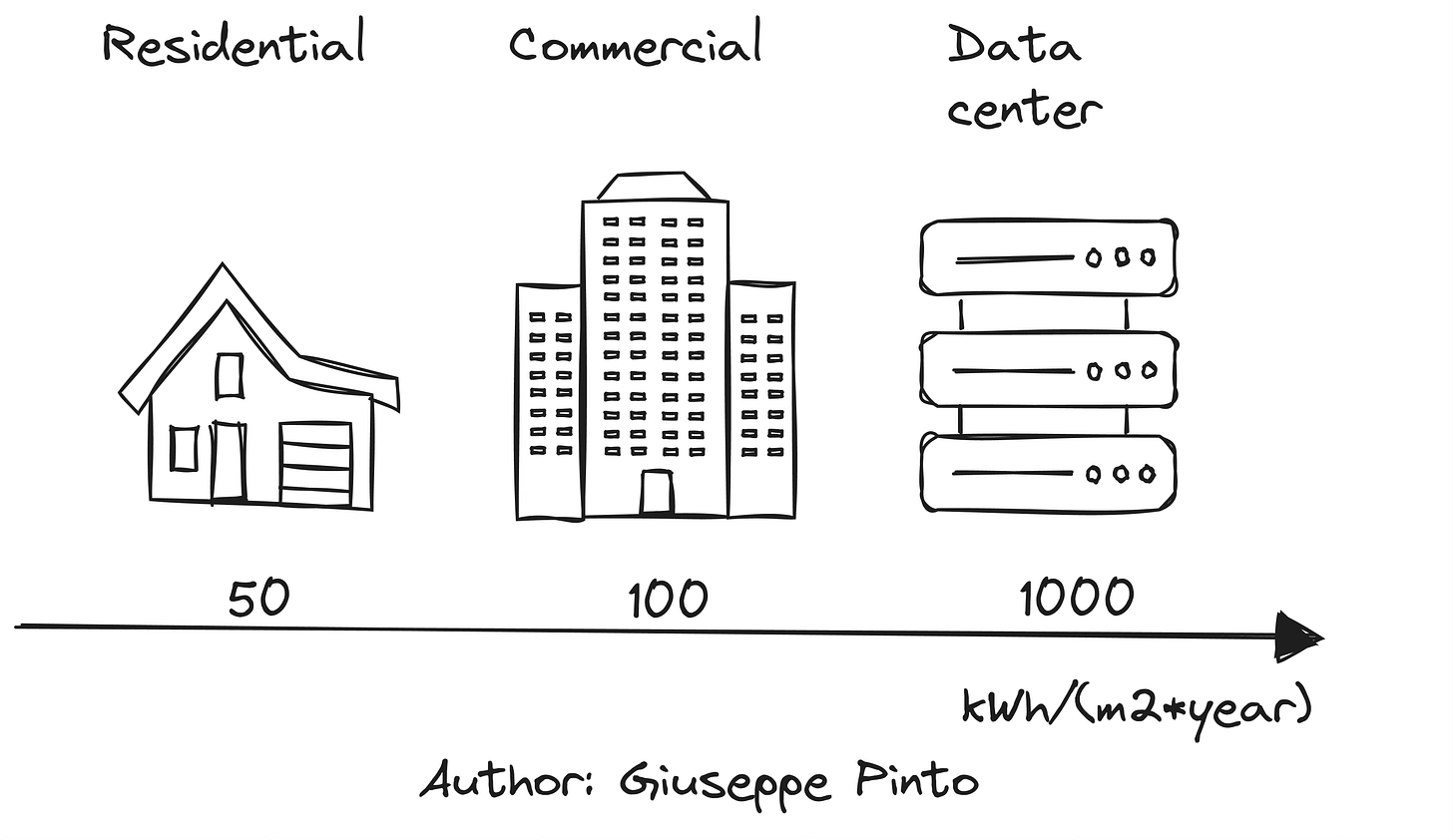

Now, let’s consider an average value of consumption based on use cases. A residential building has a HVAC related consumption that can vary from 10 to 100 kWh per square meter (let’s consider 503). For commercial buildings, the value is slightly higher, typically 100-150 kWh per square meter. In more energy-intensive applications, such as data centers, consumption can reach up to 1000 kWh per square meter.

This means that, at a cost of around 20-25 cents per kWh, the annual energy cost varies from 10-15 euros (for residential buildings), 20-30 euros (for commercial buildings), to 200-300 euros (for data centers) per square meter.

While these numbers are approximations and should be taken with a grain of salt, they provide an idea of the potential advantages an advanced controller can offer, explaining why data centers are often the initial testbeds for many companies.

The remaining question is: “given the fact that the savings can only be so much, how can we mainstream the use of advanced controllers?”

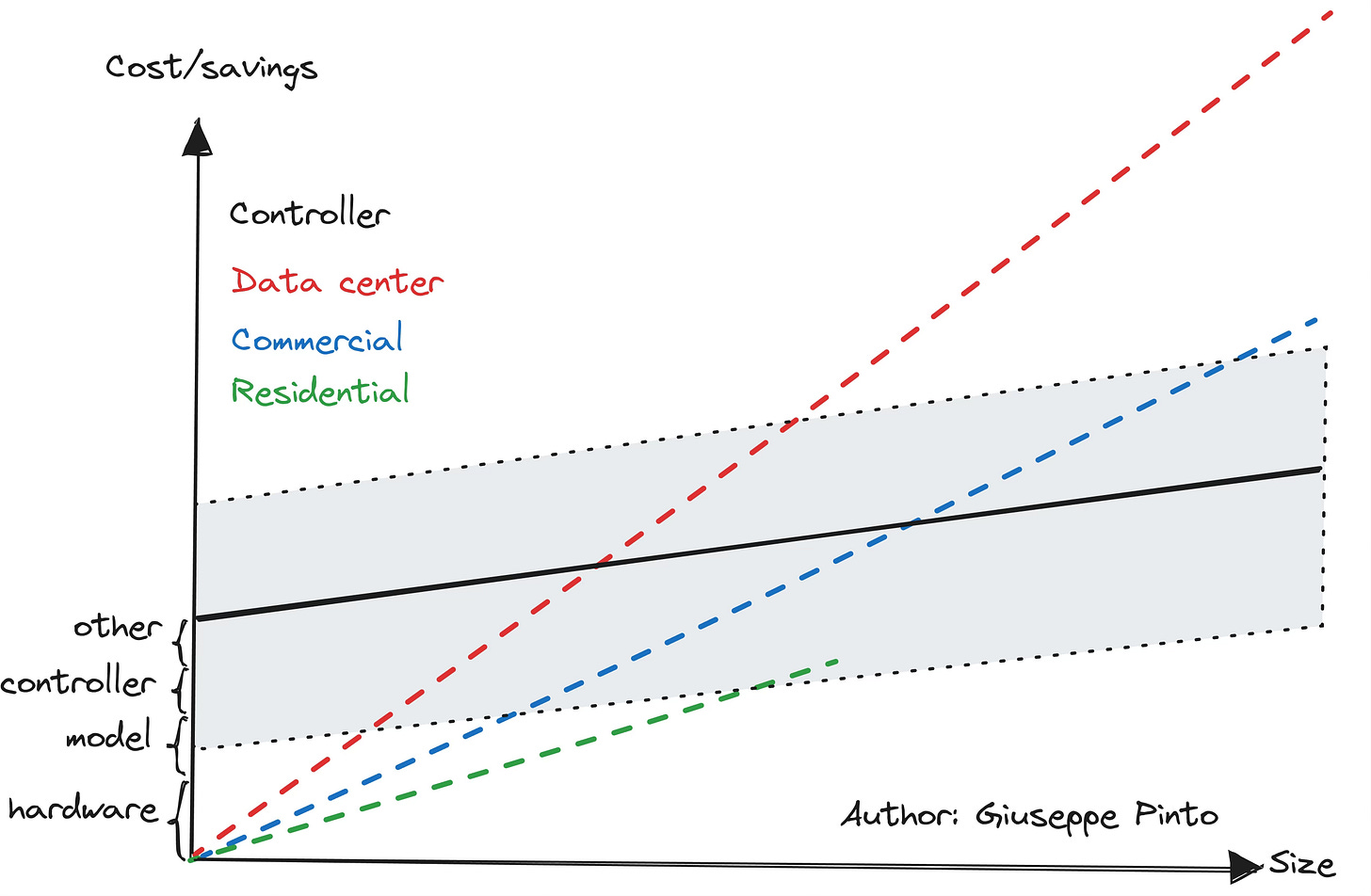

The only alternative is reducing the costs, that can be summarised as:

Costs for the hardware (sensors+controller or sensors+cloud)

Costs associated with designing and tuning the the model

Costs associated with designing and tuning the controller

Other costs (maintenance, installation, integration)

The picture above shows the savings achieved and the costs associated with an advanced controller for different types of uses, and how these factors evolve with the size of the project. There is a minimum size that justifies the costs for data center and commercial buildings, however this line hardly intersect with residential buildings.

As a result, I think that a breakthrough in the adoption of advanced controllers will happen lowering the costs and reducing the time to deploy a controller.For example:

A control that does not rely on a lot of sensors might achieve slightly less saving but reduce the cost for new hardware installation.

A model that can be built in less time thanks to a user-friendly interface while maintaining engineering rigor reduces both time and money spent on the project.

A multi-objective controller with an intuitive design let us understand the trade-off between different objectives, taking into account the needs of different stakeholders.

In conclusion, the role of engineers in the near future is to move the needle towards faster and cheaper adoption of autonomous systems. This is, by far, the biggest challenge that I see for our industry. Ironically, it is also one of my favorite aspects of my job: "automating the automation process," dramatically lowering the barrier to entry for anyone who wants to design an autonomous controller.

The consumption here varies by a factor of 10, so the number is chosen with the sole purpose of providing an example